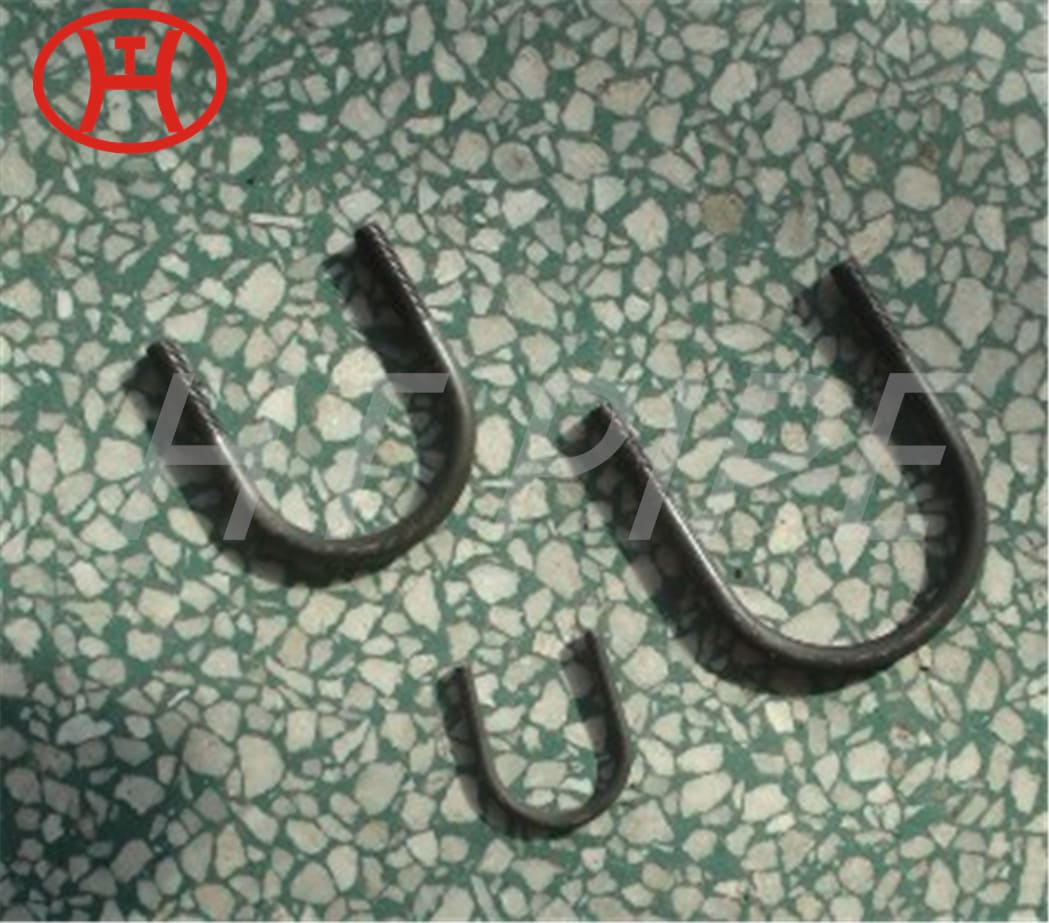

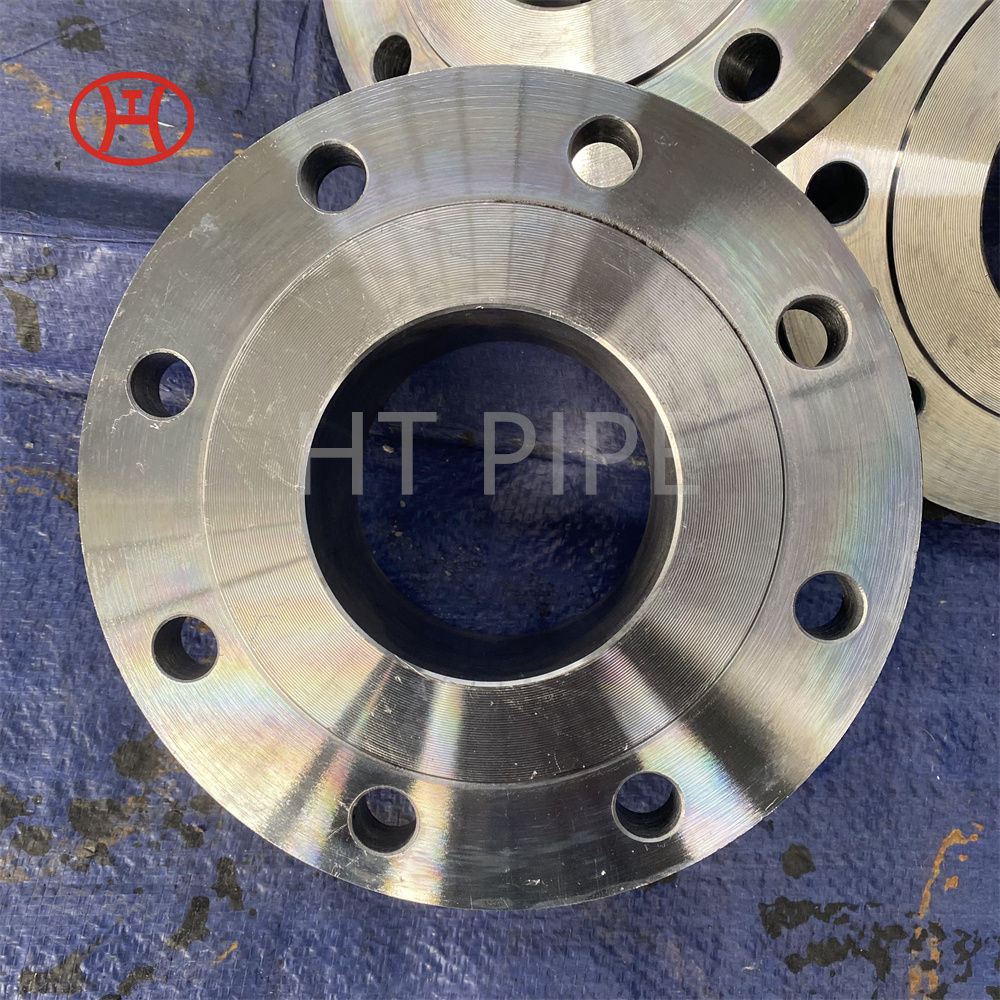

The pressure rating of pipe fittings Hastelloy C22 pipe bend

C-22 is a great alternative when superaustenitic stainless steels (AL-6XN, 904L, and 254 SMO) and duplex stainless steels (2205 and 2507) will not withstand extremely aggressive media. This is because it is a nickel-chromium-molybdenum-tungsten alloy with better overall resistance to uniform and localized corrosion than any other Ni-Cr-Mo alloy, like Hastelloy C-276, C-4, and alloy 625.

C22 pipe bend has excellent resistance to oxidation, carburization, and sulfidation at elevated temperatures. However, C22 should not be used at temperatures above 1250¡ãF due to the possible formation of embrittling phases. Hastelloy C-22 has exceptional resistance to a wide variety of chemical process environments, including strong oxidizers such as ferric and cupric chlorides, hot contaminated media (organic and inorganic), chlorine, formic and acetic acids, acetic anhydride, and seawater amd brine solutions. Hastelloy C-22 resists the formation of grain boundary precipitates in the weld heat affected zone, thus making it suitable for most chemical process applications in the as-welded condition. C22 pipe bend is typically provided in the annealed condition with a minimum yield strength of 45 ksi. However, C22 can be cold worked to higher strength levels.