titanium round bar price Inconel 718 bar WERKSTOFF NR. 2.4668 bar

Inconel 718 is often used in gas turbine components and cryogenic storage tanks. Jet engines, pump bodies and parts, rocket engines and thrust reversers, nuclear fuel element gaskets, hot extrusion tools. Other popular uses are high-strength bolted connections and downhole shafting.

Nickel alloys such as Inconel 718 are ideal for high temperature applications, as most other metals become brittle or oxidize when exposed to high temperatures. However, nickel-based alloys rapidly form a protective oxide layer when heated in an oxygen-containing atmosphere, preventing further oxidation. It also has a relatively high melting point.

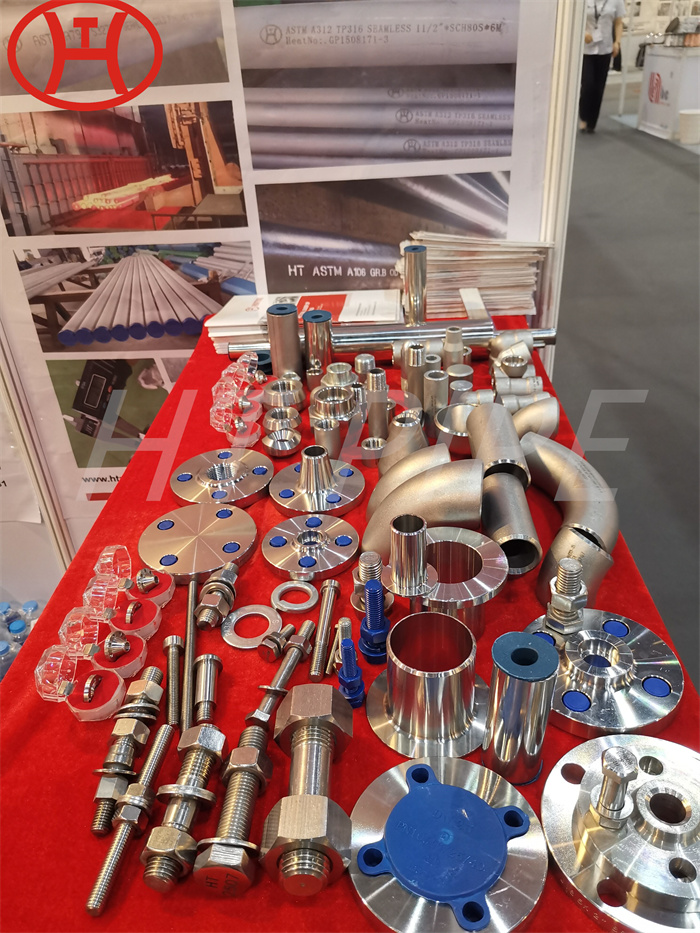

Inconel 718 bar offers very high levels of properties including corrosion resistance and high strength. As a result, applications will lean towards more aggressive environments as load-bearing components. Oil and gas and chemical processing industries have a wide range of applications, but include wellhead and downhole components, jackets, fasteners, gate valves, choke stems, packers, tubing hangers and others for corrosive/sour service project.

Additionally, nickel- and cobalt-based corrosion-resistant, temperature-resistant and wear-resistant alloys, such as Inconel 718, are classified as moderate to difficult when machined, but it should be emphasized that these alloys can be produced using conventional production methods. Machining at a satisfactory speed. During machining, these alloys harden rapidly, generate high heat during cutting, weld to the cutting tool surface, and provide high resistance to metal removal due to their high shear strength.