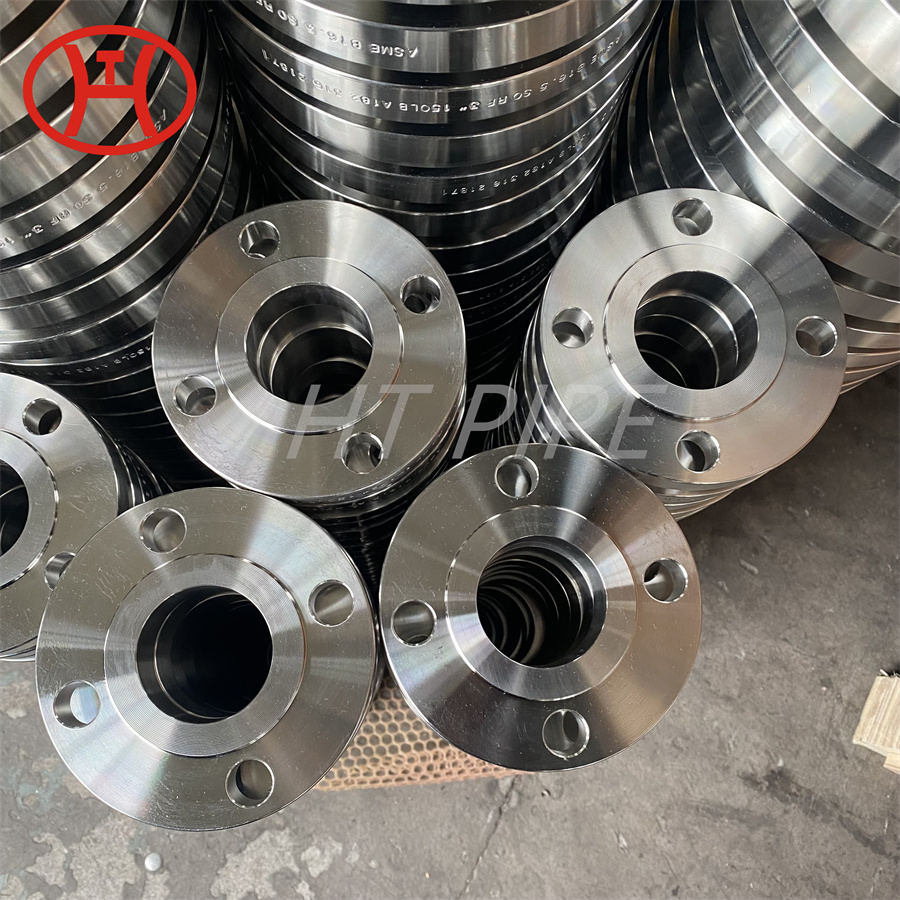

UNS S30400 Socket Weld Flange SS 304 Flange

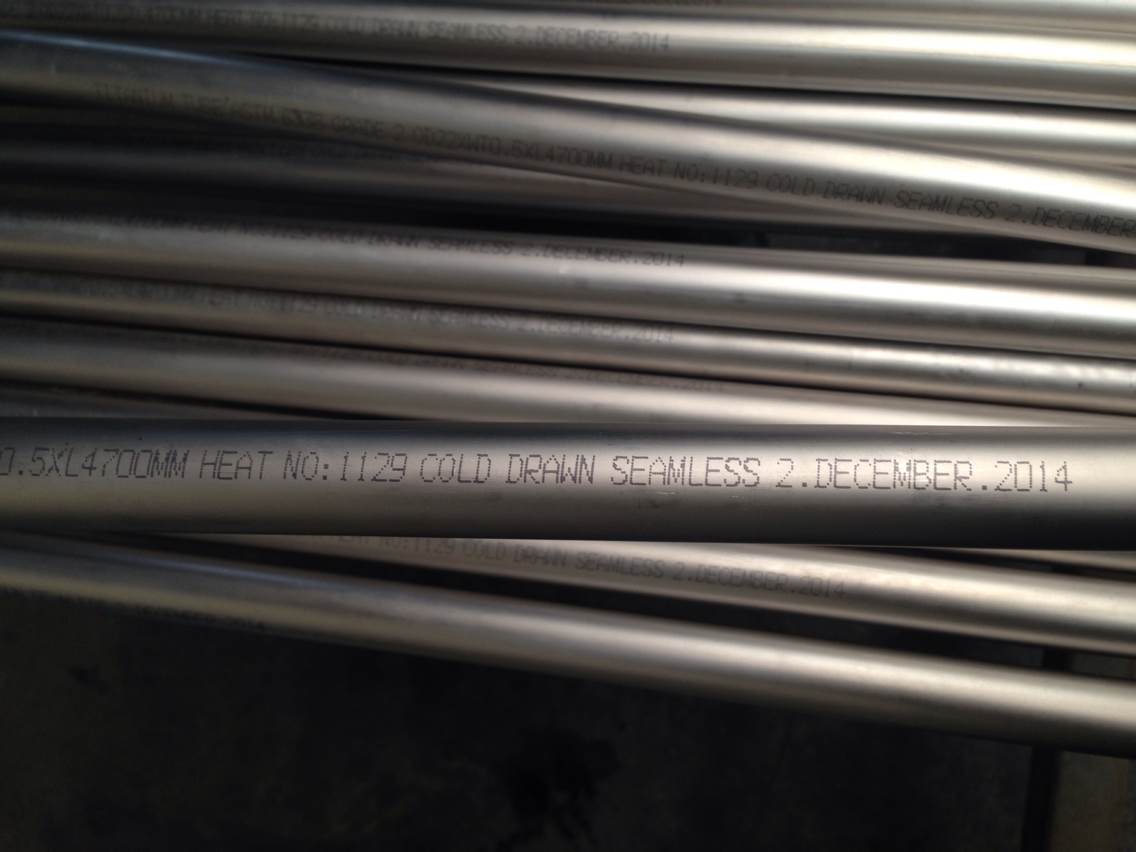

While the chemistry of Stainless Steel 304L Flanges is similar to grade 304, there are some changes done to its chemical composition. The modification in the chemistry of grade 304L improves its properties like weldability.

ASTM A182 F304L Blind Flange, SA 182 F 304L Stainless Steel Weld Neck, Slip On, Socket Weld Flanges Manufacturer In China

Stainless Steel 304L Flanges are not limited to only to its economical cost, but also includes its relative ease in weldability. The improved weldability is on account of the lowering of carbon content in the UNS S30403 SS 304L Flange. Typically a lowering the content of carbon eliminates the formation of carbide precipitates on the grain boundary. Hence, the chances for intergranular corrosion occurring in the ASTM A182 F304L Flanges are slim. Another fact that cannot be discounted is that even in the presence of severely corrosive compounds, these flanges could be used in an as welded condition. Manufacturers are also able to produce the ASME B16.11 Cl3000 A182 F304L Slip On Flanges, without the need of annealing the components.

However, annealing is required in those applications that mention or specify stress relieving. The mechanical properties of a UNS S30403 SS 304L Flange are slightly lower to that of grade 304. But, the addition of austenite balancing element such as nitrogen, improves these properties significantly, making up for the reduced carbon content. The corrosion resistance properties of both 304 & 304L are similar. Werkstoff No 1.4301 304L Stainless Steel Flanges are well suited for applications in industries like chemical processing, dairy and food industry. The textile industry is known to make use of several harsh and corrosive chemicals to process materials. Since the production of textiles is very expensive, most manufacturers are in search of cost saving alternatives. Which is why using SA 182 F304L Blind Flanges is not only economical, but 1.4301 304L Stainless Steel Flange also resistant to several chemicals, making 304L Stainless Steel Flange a commercially viable product.

Werkstoff No 1.4301 Stainless Steel Industrial Flanges Specification

| Specifications | ASTM A182, ASME SA182 |

| ASME B16.5 304 SS Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| ASTM A182 Stainless Steel 304L Flanges Standards | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges, ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Main Types | Forged / Threaded / Screwed / Plate |

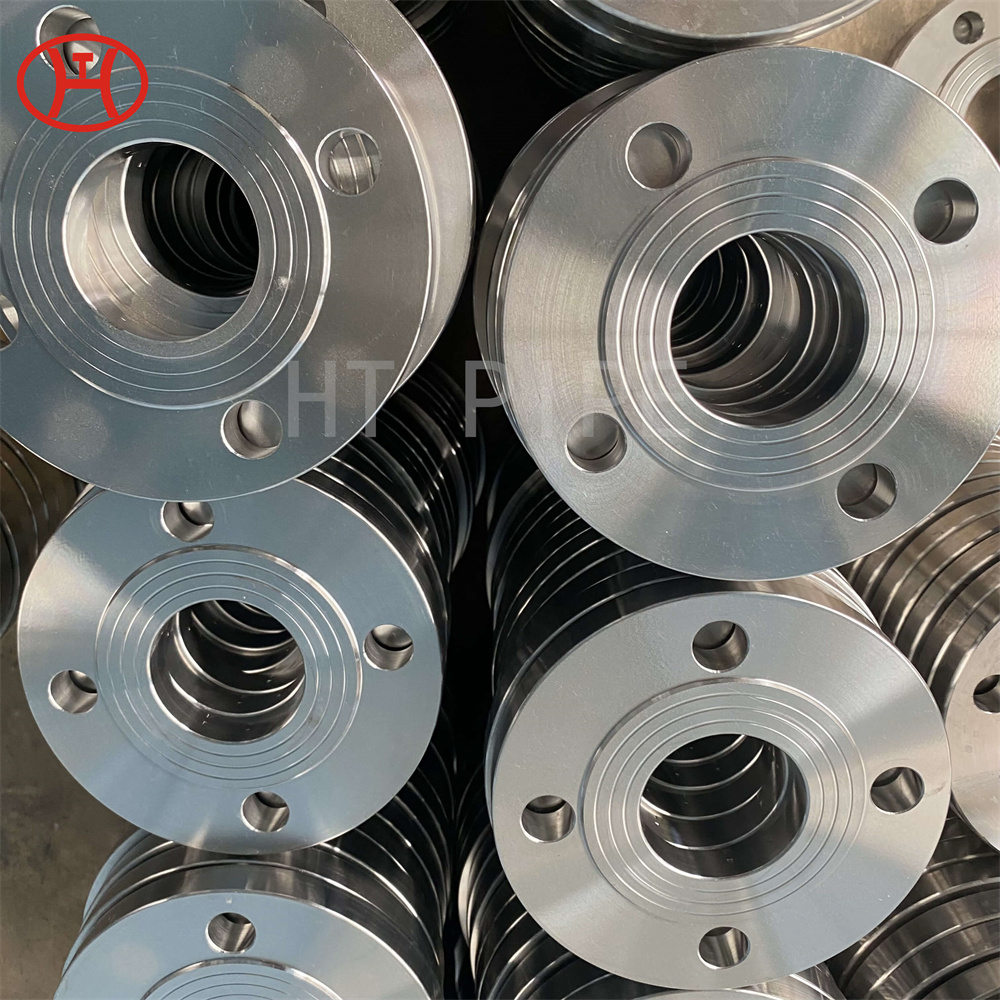

| Types of Stainless Steel 304/304L Flanges | Blind Ring Flange (BLRF) |

| Lap Joint Ring Flange (LJRF) | |

| Socket Weld Ring Flange (SWRF) | |

| Threaded Ring Flange | |

| Weld Neck Ring Flange (WNRF) | |

| Slip-On Ring Flange (SORF) | |

| Ring Type Joint Flange (RTJF) | |

| Manufacturers of ASTM A182 F304/F304L Flanges | ASTM A182 304 Flanges make Erne Fittings, Austria |

| ASME SA182 F304L Alloy Flanges make Melesi, Italy | |

| 304 SS Flanges make Raccortubi S.p.A., Italy | |

| SS 304L Flanges make Ulma, Spain | |

| Stainless Stee 304 ANSI Flanges make Mega, Italy | |

| Stainless Steel 304H Alloy Flanges make TecnoForge, Italy | |

| 304L Stainless Steel Flange Pressure Ratings | DIN:PN6 PN10 PN16 PN25 PN40; ANSI: |

| class: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, | |

| DIN Standard ND-PN6, PN10, PN16, PN25, PN40, PN64 etc. | |

| JIS: 5K, 10 K, 16 K 20 K,30 K,40 K, 63 K; | |

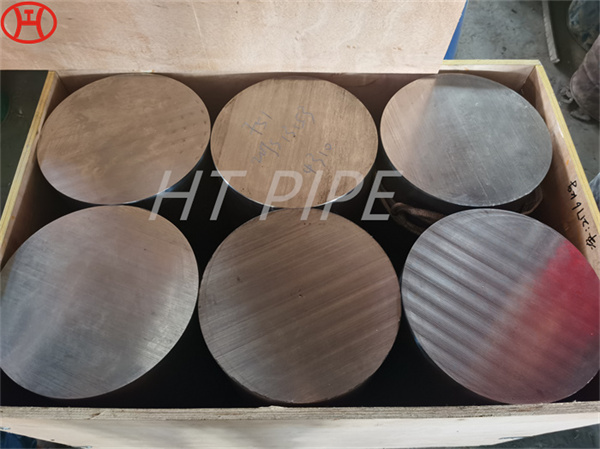

| Production technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Ring Type Joint (RTJ), Flat Face (FF), Lap-Joint Face (LJF), Raised Face (RF), Large Male-Female (LMF), Small Male-Female (SMF), Large Tongue & Groove, Small Tongue, Groove |