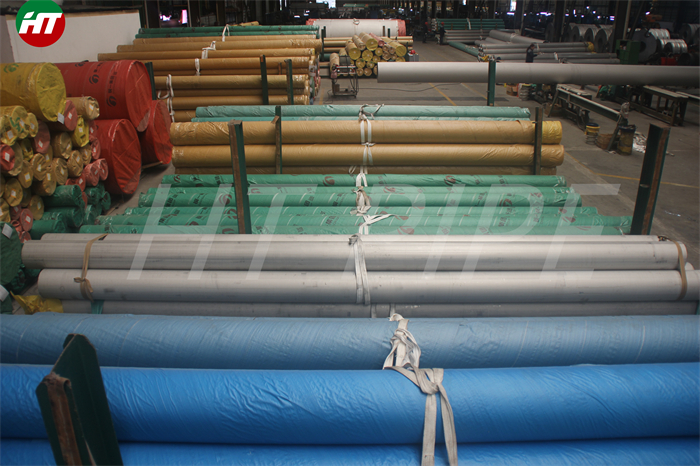

Welded stainless steel pipe astm a 312 tp 304 304l

304L stainless pipe has slightly lower mechanical properties than standard 304 grades, but is still widely used due to its versatility. Like Type 304 stainless steel, it is commonly used in beer brewing and winemaking, but is also used outside of the food industry, such as chemical containers, mining and construction. It is ideal for metal parts such as nuts and bolts exposed to salt water.

Stainless Steel DIN 1.4307 Welded Pipe, 304L SS Pipe, SS UNS S30403 Pipes, ASTM A312 TP304L ERW Pipe, Check Stainless Steel 304L Seamless Pipe Price List

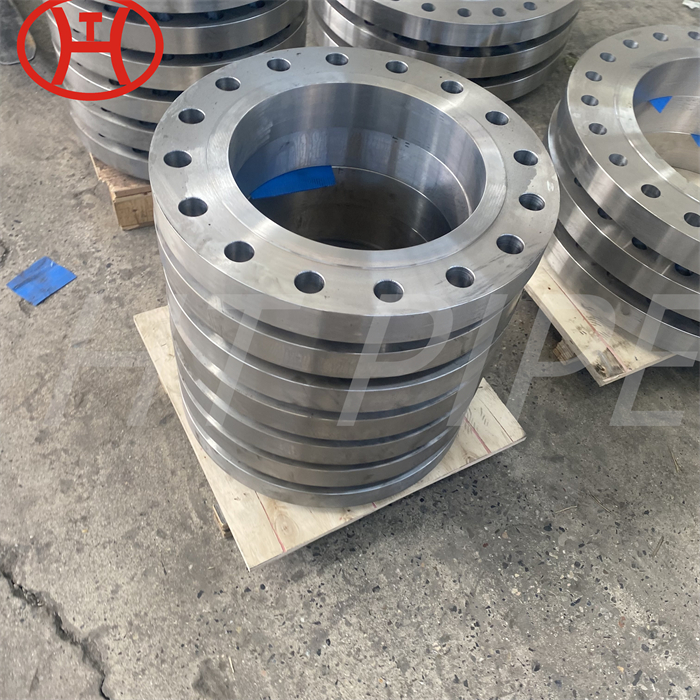

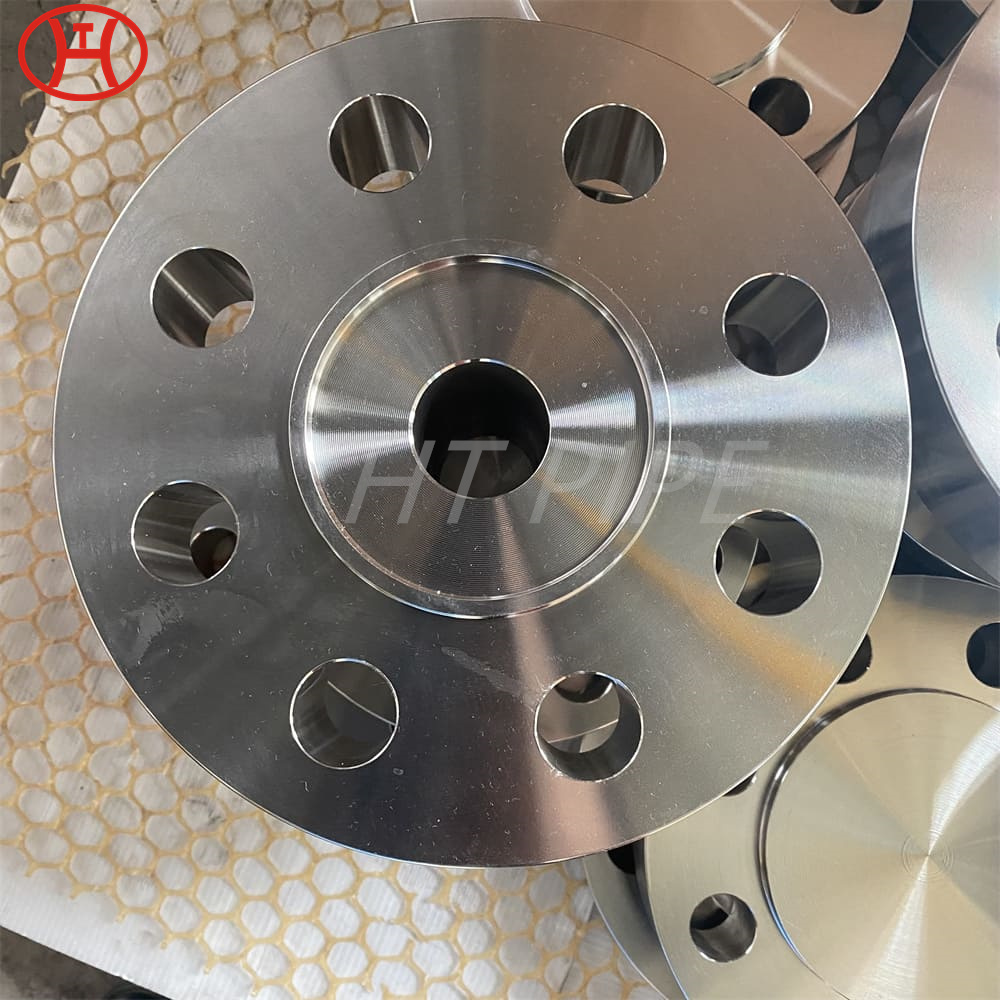

304L SS Pipes are the most versatile and commonly used austenitic chromium-nickel alloys on the market. The chromium content in the alloy promotes excellent corrosion resistance, high strength-to-weight ratio, and remarkable ductility. As the predominant choice for hydraulic and instrumentation tubing, SS UNS S30403 Pipe possess exceptional welding capabilities.

304/304L Stainless steel tube is a versatile stainless steel that is widely used in manufacturing the equipment and components that require good overall performance (corrosion resistance and formability). ASTM A312 TP304L ERW Pipe is produced in accordance with the United States ASTM standard stainless steel a grade. 304 equivalent to China’s 0Cr19Ni9 (0Cr18Ni9) stainless steel. 304 containing chromium 19%, containing nickel 9%. 304 is the most widely used stainless steel, heat-resistant steel, practical steel, steel industry. For food production equipment, general chemical equipment, nuclear energy and so on. In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 12% of the chromium.

Stainless Steel 304L Seamless Pipe, or 18-8 as it is sometimes called, combines remarkable resistance to many corrosive environments with mechanical properties similar to most structural steels. Stainless Steel DIN 1.4307 Welded Pipe is non-magnetic in the annealed condition and not hardenable by heat treatment. Its strength can be improved by cold work. Type 304/304L or the low Carbon version (.03 max) of 304/304L should be used when welding is required.

Chemical Requirements

|

UNS |

C Carbon |

Mn |

P |

S |

Si |

Cr |

Ni Nickel |

|

S30400 |

0.080 max |

2.00 max |

0.045 max |

0.030 max |

1.00 max |

18.0–20.0 |

8.0–11.0 |

|

S30403 |

0.030 max |

2.00 max |

0.045 max |

0.030 max |

1.00 max |

18.0–20.0 |

8.0–12.0 |

|

Yield Strength: |

30 ksi min |

|

Tensile Strength: |

75 ksi min |

|

Elongation (min 2″): |

35% |

|

Hardness (Rockwell B Scale): |

90 HRB max |