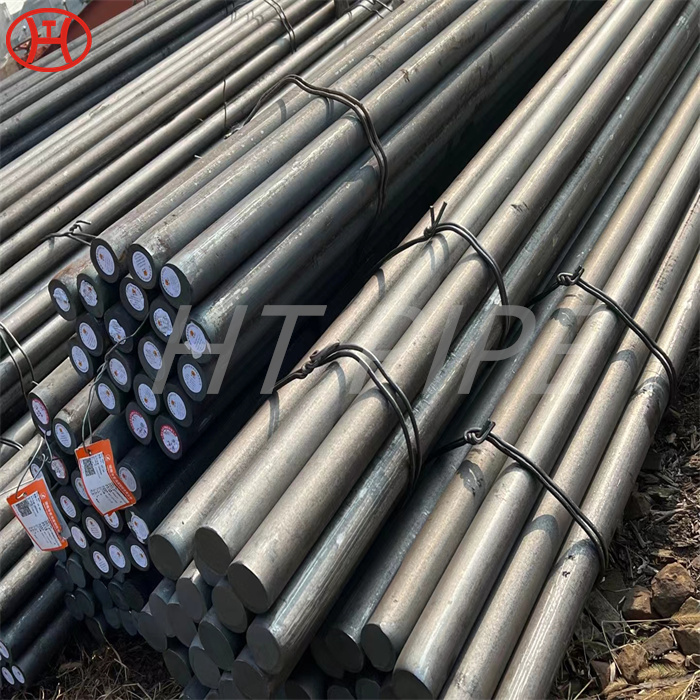

nickel alloy monel 400

Alloy 400 has excellent resistance to neutral and alkaline salts. It has been the standard material in salt mills for many years.

Standard SUS, AISI, DIN

Diameter 5~500mm

Length ¨Q12M or As Per Clients’ Requirements

The alloy is one of the few metal materials that can be in contact with fluorine and hydrofluoric acid

acid, hydrogen fluoride or other derivatives. Alloy 400 has very high resistance to caustic. The performance in seawater is also very good, with higher cavitation resistance than copper-based alloys. It can be used in contact with dilute solutions of mineral acids, such as sulfuric and hydrochloric acids, especially if they are air-free. However, since the alloy does not contain chromium, the corrosion rate may increase significantly under oxidizing conditions. While Alloy 400 can be considered immune to chloride stress cracking, it can stress crack in the presence of mercury or most gas-filled HF vapors. In this case, a stress relief heat treatment is applied.

Standard SUS, AISI, DIN

Diameter 5~500mm

Length ¨Q12M or As Per Clients’ Requirements

Material: Nickel Alloy ASTM/ASME SB 425 Alloy 825/Incoloy 825/UNS N08825

ASTM/ASME SB 446 Alloy 625/UNS N06625

ASTM/ASME SB164 Monel 400/Alloy 400/UNS N04400

ASTM/ASME SB 408 Alloy 800HT/Incoloy 800HT/UNS N08811, Alloy 800/Incoloy 800/UNS N08800, Alloy 800H/Incoloy 800H/UNS N08810

ASTM/ASME SB 649 Alloy 925/Incoloy 925/UNS N09925, Alloy 926/Incoloy 926/UNS N08926, Alloy 31/UNS N08031

ASTM/ASME SB 166 Alloy 600/Inconel 600/UNS N06600,Alloy 601/Inconel 601/UNS N06601

ASTM/ASME SB160 Alloy 200/UNS N02200, Alloy 201/UNS N02201

ASTM/ASME SB 472 Hastelloy C-276/UNS N10276,Alloy 926/Incoloy 926/UNS N08926, Alloy 31/UNS N08031,Alloy 20/N08020, Alloy C-22/Hastelloy C-22/N06022, Alloy 600/Inconel 600/UNS N06600,

ASTM/ASME SB 473 Alloy 20/UNS N08020

ASTM/ASME SB 574 Hastelloy C-276/UNS

N10276

ASTM/ASME SB 637 Alloy 718/Inconel 718/N07720