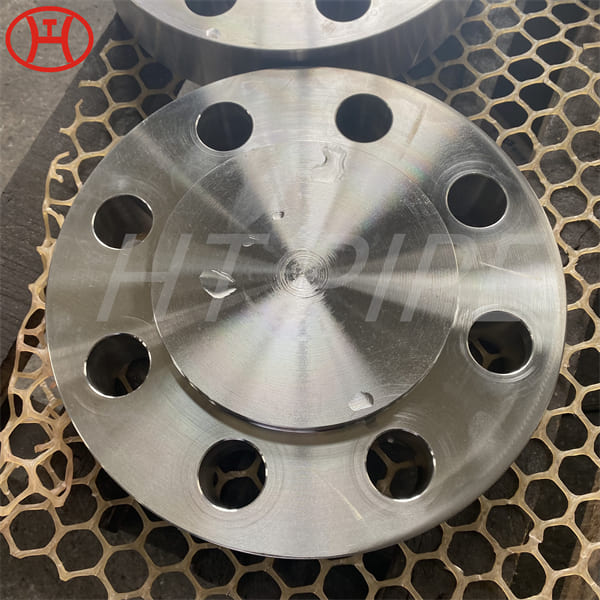

Stainless Steel 310 Flanges SS 310S Blind Flanges Dealer

Stainless Steel 310 Flanges are made up of a stainless steel grade that has high amounts of nickel and chromium. It is a chromium nickel alloy with 24% chromium and 19% nickel in the composition. Navstar Steel is a leading manufacturer and supplier of the Stainless Steel 310 Flanges in different variations.

STAINLESS STEEL 310 FLANGES, 310 STAINLESS STEEL FLANGES, SS 310 FLANGES, ASTM A182 F310, ASME SA182 F310 FLANGES MANUFACTURER IN CHINA.

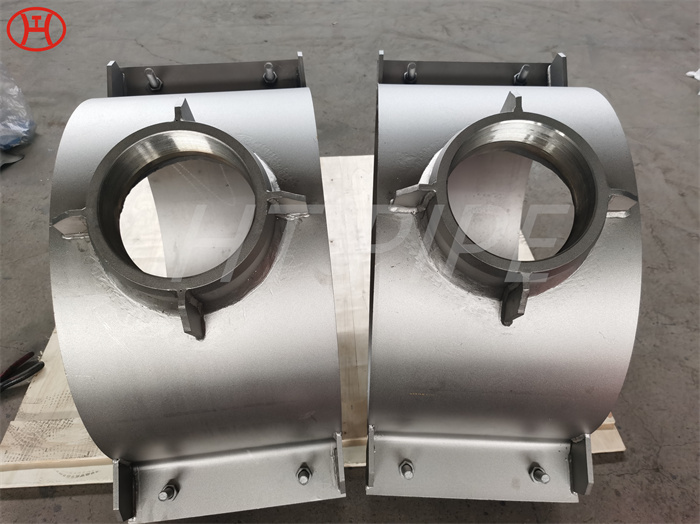

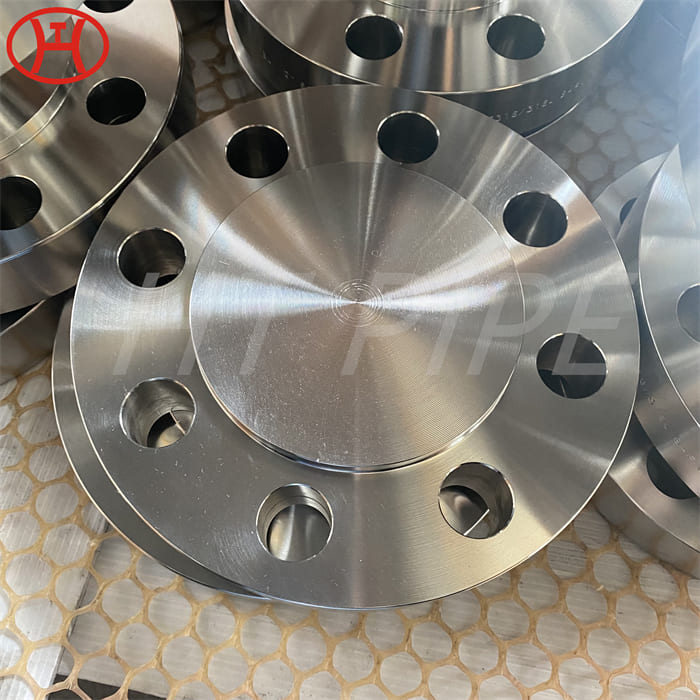

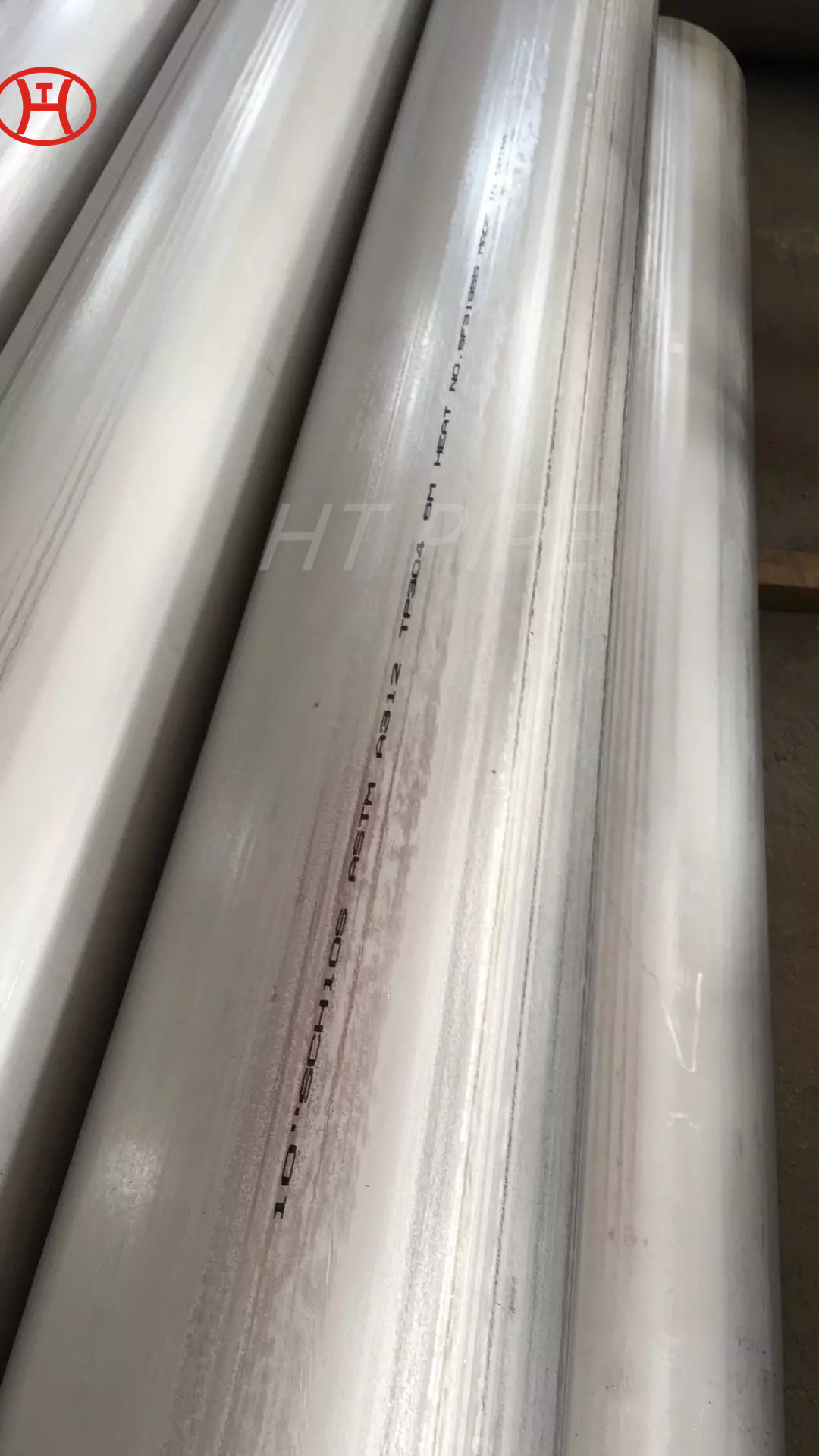

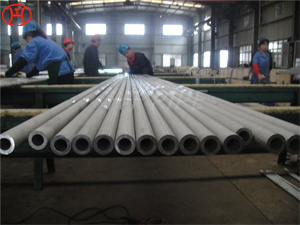

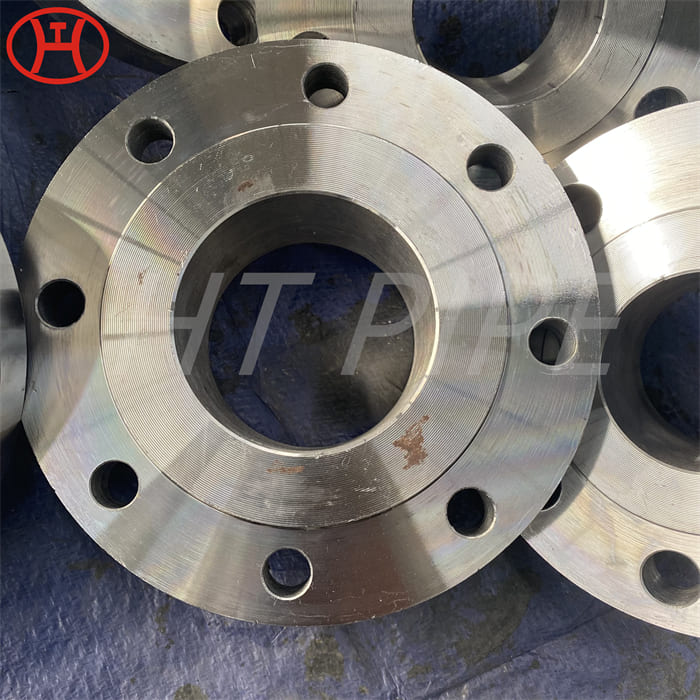

Stainless Steel 310 Flangeis a method of connecting pipes, valves, pumps and other equipment to form a piping system. SS Grade F310 Blind Flange also provides easy access for cleaning, inspection or modification. A182 310 SS Plate Flanges are usually welded or screwed. Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal. HT PIPE is an ISO 9001:2000 certified manufacturer of ASTM A182 F310 Stainless Steel Flanges.We are leading exporter and supplier of SS DIN 1.4845 Flanges those are conforms to quality parameters of design, standard and class. ASME B16.47 310 Pipe Flange are produced and supplied through a planned and well-executed strategy of swifter consignment packaging and delivery procedure. 310S Stainless steel Flanges are applicable for high temperature applications such as furnace parts and heat treatment equipment.

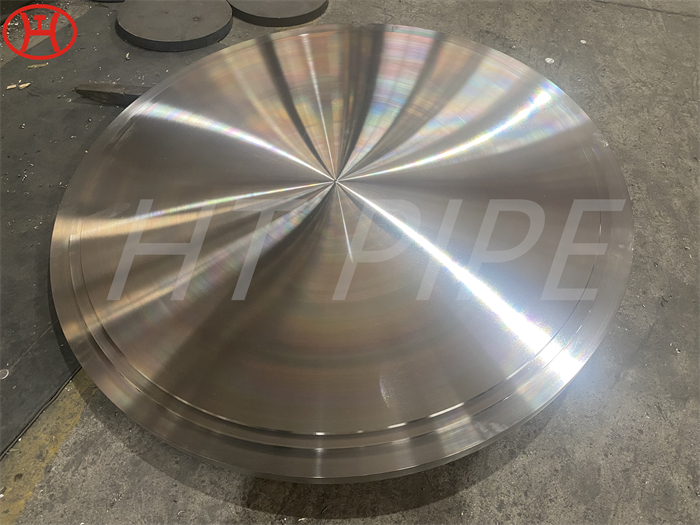

Grade 310 Stainless Steel Pipe flange is often used in cryogenic applications, due to its toughness and low magnetic permeability.Corrosion Resistance of ASTM A182 SS 310S Slip On Flange is not contain molybdenum because if that pitting resistance is entirely poor. A182 F310/F310S Flange have good resistance to oxidation in intermittent service in air up to 1035¡ãCand 1050¡ãCin continuous service.We offer wide range of Stainless Steel ASTM A182 310S Orifice Flanges, ANSI B16.5 310 Threaded Flanges and 310S stainless Steel Blind Flange.We offer ASME B16.48 310 Plate flange at best price. HT PIPE is one of the prominent dealer and whole seller for high quality SS 310 / 310S Flanges, where the heat treatment is given on the continuously rolling hearth furnace and the furnace is fitted with temperature recorders and controllers. After the heat treatment process, Stainless Steel 310 Slip On Flanges and pipes are straightened and subjected to pickling for removing scales from the surface. In some cases, the required size of Stainless Steel 310S Threaded Flanges may not be obtained from the mill directly, so then the cold operation process can be used to obtain the desired size. In cold drawing process, Stainless Steel 310S Weld Neck Flanges are coated with oxalic and soap solution.

ANSI B16.5 SS 310S Slip On Flanges Pressure

| ANSI/ASME B16.34 | PRESSURE RATING CHART | ||||||

| Temperature °F | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 275 | 720 | 960 | 1440 | 2160 | 3600 | 6000 |

| 200 | 230 | 600 | 800 | 1200 | 1800 | 3000 | 5000 |

| 300 | 205 | 540 | 720 | 1080 | 1620 | 2700 | 4500 |

| 400 | 190 | 495 | 660 | 995 | 1490 | 2485 | 4140 |

| 500 | 170 | 465 | 620 | 930 | 1395 | 2330 | 3880 |

| 600 | 140 | 435 | 580 | 875 | 1310 | 2185 | 3640 |

| 650 | 125 | 430 | 575 | 860 | 1290 | 2150 | 3580 |

| 700 | 110 | 425 | 565 | 850 | 1275 | 2125 | 3540 |

| 750 | 95 | 415 | 555 | 830 | 1245 | 2075 | 3460 |

| 800 | 80 | 405 | 540 | 805 | 1210 | 2015 | 3360 |

| 850 | 65 | 395 | 530 | 790 | 1190 | 1980 | 3300 |

| 900 | 50 | 390 | 520 | 780 | 1165 | 1945 | 3240 |

| 950 | 35 | 380 | 510 | 765 | 1145 | 1910 | 3180 |

| 1000 | 20 | 320 | 430 | 640 | 965 | 1605 | 2675 |

| 1050 | 20 | 310 | 410 | 615 | 925 | 1545 | 2570 |

| 1100 | 20 | 255 | 345 | 515 | 770 | 1285 | 2145 |

| 1150 | 20 | 200 | 265 | 400 | 595 | 995 | 1655 |

| 1200 | 20 | 155 | 205 | 310 | 465 | 770 | 1285 |

| 1250 | 20 | 115 | 150 | 225 | 340 | 565 | 945 |

| 1300 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

| 1350 | 20 | 60 | 80 | 125 | 185 | 310 | 515 |

| 1400 | 20 | 50 | 65 | 95 | 145 | 240 | 400 |

| 1450 | 15 | 35 | 45 | 70 | 105 | 170 | 285 |

| 1500 | 10 | 25 | 35 | 55 | 80 | 135 | 230 |