What is a Pipe Saddle?

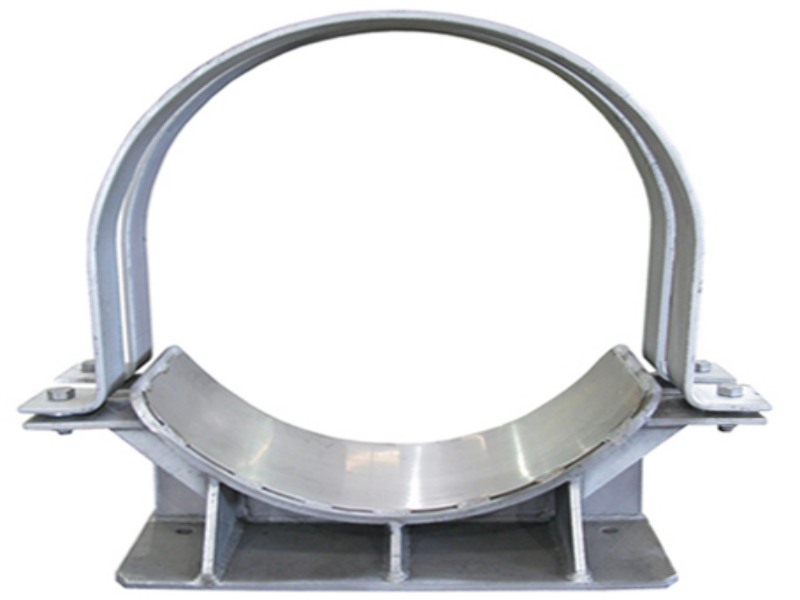

A pipe saddle is any pipe support that cradles a pipe and transfers the load of the piping system onto secondary members through its supporting base. In the piping industry, a pipe saddle is characterized by two distinct features: A saddle that supports the pipe, an integral base for transferring the loads from the piping system to the civil structure.

Pipe saddles are structures consisting of a saddle and integral base that are used to support pipes by transferring loads or forces to adjacent structures. Pipe saddles are ideal components for making pipe supports and brackets, as well as for any structural needs within sanitary process areas. These pipe accessories make building structures such as frames and bases quick and simple.

Pipe saddles range in size from 20mm to 200mm. They allow pipes to expand without damaging insulation and help prevent damage caused by friction with other pipes. With large amounts of liquids and corrosive elements bearing down on your pipes, it is best to provide them with some form of support. Installing a pipe saddle can be an easy way to transfer the weight of the pipe load to a supporting base.

Pipe saddles can make your pipe system stronger for longer service, saving you money in the long run. A few of the more common ways these saddles protect pipes are by elevating, anchoring, and adding adjustable support. When pipes are resting on bare ground or dirty surfaces, elevating them can prevent corrosion. If your pipes are heavy, any movement can damage the pipe surface, and pipe saddles can cushion the force of movement, elevate the pipe, and secure the pipe.

Design Parameters for Pipe Saddles

Saddle material:

Pipe saddle material should be compatible with the parent pipe material. Also, the material should have sufficient strength to handle the loads generated in the pipe system. The common saddle material is Carbon Steel (CS). However, they can be made of other materials as well. Sometimes, to reduce the cost a combination of materials can be used. For example, to support stainless steel (SS) pipe using a pipe saddle the complete design of the saddle may not use SS material. It can easily use the SS+CS combination to reduce costs. Wherever it touches the SS pipe, the material must be SS but other parts can be of CS material.

Piping Loads:

Piping load is the main important input required while designing saddle supports. The material thickness, strengthening requirement, weld size, etc all will be based on the load that needs to be supported. Loads in all directions must be considered in saddle design.

Thermal movement of pipe at the Support Location:

The maximum thermal displacement at the saddle location must be known while designing the saddle base. The base of the pipe saddle support must be sized such that it does not fall off the structural member due to.