Incoloy 800HT is an iron-nickel-chromium alloy having the same basic composition as Incoloy 800 and Incoloy 800H but with significantly higher creep-rupture strength. The higher strength results from deliberate control of the carbon, aluminum, and titanium contents in conjunction with a high-temperature anneal. Used in chemical and petroleum processing, in power plants for superheater and reheater tubing, in industrial furnaces, and for heat treating equipment.

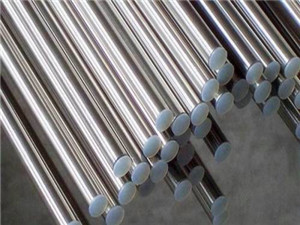

HT PIPE provide Incoloy 800HT Nickel alloy round bar, Alloy 800HT Bar supplier in China. 1.4876 round bar, Alloy 1.4859 rod, UNS N08811 rod, Alloy 800HT flat Bar, Incoloy 800HT hollow bar, Incoloy 800HT Nickel alloy round bar supplier, exporter

| Standard |

ASTM / ASME SB 166, ASTM / ASME B 446 , ASTM / ASME B 637, ASTM B 511, ASTM B 408 |

| Size |

5 mm To 500 mm Dia in 100 mm TO 6000 mm Length available with NACE MR 01-75. |

| Length |

100 mm To 3000 mm Long & Above |

| Finish |

Bright, Polish & Black |

| Form |

Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging

|

JIS NCF 800/800H/800HT Incoloy® Alloy Round Bar Equivalent Indian Standard

|

STANDARD

|

UNS

|

WNR.

|

AFNOR

|

EN

|

JIS

|

BS

|

GOST

|

OR

|

|

Incoloy 800

|

N08800

|

1.4876

|

Z8NC32-21

|

X10NiCrAlTi32-20

|

NCF 800

|

NA 15

|

ЭИ670

|

XH32T

|

|

Incoloy 800H

|

N08810

|

1.4958

|

Z8NC32-21

|

X10NiCrAlTi32-20

|

NCF 800H

|

NA 15(H)

|

ЭИ670

|

XH32T

|

|

Incoloy 800HT

|

N08811

|

1.4959

|

-

|

X8NiCrAlTi32-21

|

NCF 800HT

|

NA 15(HT)

|

ЭИ670

|

XH32T

|

ASTM B408 Incoloy 800HT Cold Drawn Round Bar Chemical Composition

| Ni |

Cr |

Fe |

C |

Al |

Ti |

Al+Ti |

| 30.0-35.0 |

19.0-23.0 |

39.5 min |

.06-.10 |

.25-.60 |

.25-.60 |

0.85-1.2 |

ASME SB408 Incoloy® 800HT Hot-Rolled Round Bars Mechanical Properties

| Tensile Strength, min. |

Yield Strength, min. |

Elongation, min. |

Hardness, min. |

| Mpa |

ksi |

Mpa |

ksi |

% |

HB |

| 600 |

87 |

295 |

43 |

44 |

138 |

Physical Properties of Incoloy 800HT

| Density |

Melting Range |

Specific Heat |

Electrical Resistivity |

| g/cm3 |

°C |

°F |

J/kg. k |

Btu/lb.°F |

µΩ·m |

| 7.94 |

1357-1385 |

2475-2525 |

460 |

0.11 |

989 |

.jpg)