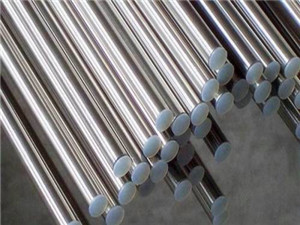

Bright Black surface ASTM B166 B472 Alloy 600 UNS N06600 DIN 2.4816 Inconel 600 Steel Round Bar Rod

HT PIPE provide Inconel 600 Nickel alloy round bar, Alloy 600 Bar supplier in China. 2.4816 round bar, UNS N06600 rod, Alloy 600 flat Bar, Inconel 600 hollow bar, Inconel 600 Nickel alloy round bar supplier, exporter

1. INCONEL 600 ROUND BAR

Inconel 600 is a chromium-nickel alloy designed for use at temperatures up to 2000°F and down to as low as cryogenic levels. The alloy is resistant to reducing environments as well as chloride stress corrosion cracking due to its nickel content and resistant to weaker oxidizing conditions through it’s chromium content. Inconel 600 is an austenitic alloy with high nickel content that is non-magnetic and has excellent mechanical properties at both high temperatures and cryogenic temperatures. The nickel content does make this alloy susceptible to attack at elevated temperatures in sulfur bearing atmospheres.

Nickel Alloy 600, additionally sold under the brand name Inconel Alloy 600. Nickel Alloy Corporation is a leading supplier and exporter of Inconel 600 Round Bar. We provide Inconel Alloy 600 Round Bar globally as per made-to-order requirements given by our highly valued clients, to meet the quality demands of our customers. Inconel Alloy 600 Round Bar comes in sizes from 8mm to 300mm.

Inconel Alloy 600 Round Bars is a nickel-base compound with superb carburization, and great oxidation resistance at lifted temperatures. The Inconel Alloy 600 Round Bars has for quite some time been utilized as a part of the warmth treating industry for a large number of the same applications as RA330. Inconel Alloy 600 Round Bars composite has valuable imperviousness to dry Cl2 and HCl gasses at reasonably raised temperatures. Inconel Alloy 600 Round Bars is not recommended for use at red warmth when sulfur is available because of lifted nickel amounts.

2.Inconel 600 Round Bars Equivalent Grade

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

| Inconel 600 |

2.4816 |

N06600 |

NCF 600 |

NA 13 |

МНЖМц 28-2,5-1,5 |

NC15FE11M |

NiCr15Fe |

3.Inconel 600 Round Bars Chemical Composition

| Grade |

C |

Mn |

Si |

S |

Cu |

Fe |

Ni |

Cr |

| Inconel 600 |

0.15 max |

1.00 max |

0.50 max |

0.015max |

0.50 max |

6.00 – 10.00 |

72.00 min |

14.00 – 17.00 |

4.Inconel 600 Round Bars Mechanical Properties

| Element |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Inconel 600 |

8.47 g/cm3 |

1413 °C (2580 °F) |

Psi – 95,000 , MPa – 655 |

Psi – 45,000 , MPa – 310 |

40 % |

Inconel 600 is a super alloy, which are also referred to as high performance alloys. Inconel 600 Bright Bar have the capacity to function under very high temperatures and extreme mechanical stress. Inconel 600 can be used where the end use application requires high surface stability.

As a super alloy, Inconel 600 is known to have good creep and good oxidation resistance.Inconel 600 Hex Bar can be formed using conventional methods with the help of powerful equipment as it has good ductility.

.jpg)

.jpg)

.jpg)

.jpg)