AISI 316 Stainless Steel Pipe has Molybdenum Content (2-3%), this enhances it resistance to pitting and crevice corrosion in chloride-rich environments (e.g., seawater, chemical exposure).

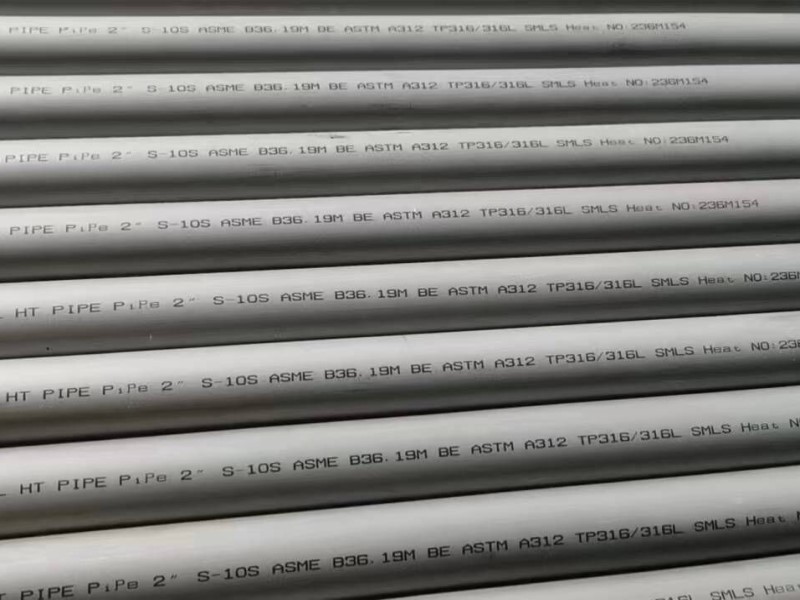

HT PIPE provide AISI 316 Stainless Steel seamless and welded Pipes and Tubes, these pipe or tube meets the ASTM A312, ASTM A213, ASTM A269, ASME B36.19M, and EN 1.4401 standards.

AISI 316 pipes are widely used in international projects:

Offshore oil platforms in the Gulf of Mexico;

Desalination plants in UAE;

Wastewater treatment plants in Scandinavia;

The mining operations in Chile

.....

AISI 316 Stainless Steel Pipe shall be manufactured by Seamless (SML) or Welded (WLD) or Heavily cold worked (HCW).

The 316 Stainless Steel welded Pipe are made using an automatic welding process with no addition of filler metal during the welding process.

Stainless steel 316 Welded pipe and HCW pipe of NPS 14 and smaller shall have a single longitudinal weld, larger than NPS 14 shall have a single longitudinal weld or shall be produced by forming and welding two longitudinal sections of flat stock when approved by the purchaser. All weld tests, examinations, inspections, or treatments shall be performed on each weld seam.

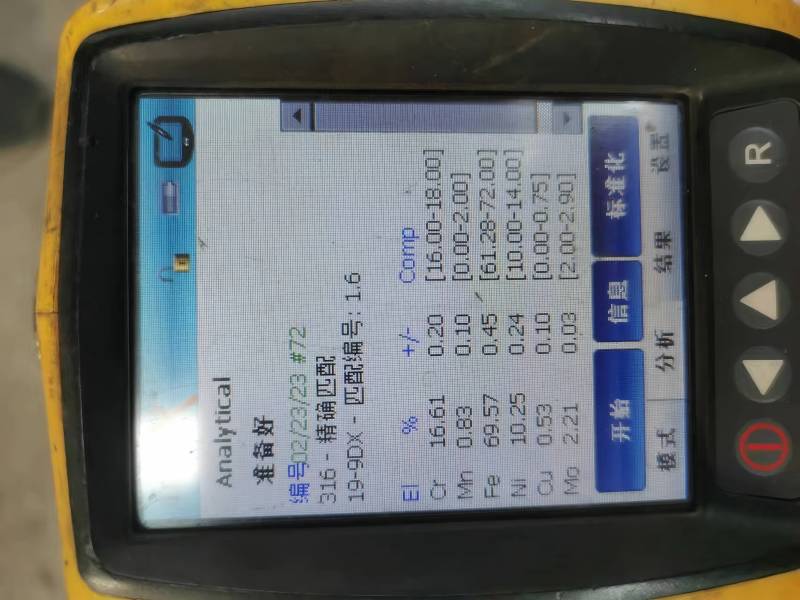

AISI 316 Stainless steel Chemical Composition:

|

Grade

|

UNS

|

C≤

|

Mn

|

P≤

|

S≤

|

Si≤

|

Cr

|

Mo

|

Ni

|

|

TP316

|

S31600

|

0.08

|

2

|

0.045

|

0.03

|

1

|

16.0-18.0

|

2.00-3.00

|

10.0-14.0

|

AISI 316 Stainless Steel Pipe Annealing Temperature Requirements:

1900°F [1040°C] (Minimum)

AISI 316 Stainless Steel Pipe Mechanical Testing:

Tensile strength (≥515 MPa), yield strength (≥205 MPa)

AISI 316 Stainless Steel Pipe Corrosion Testing:

ASTM G48 (pitting resistance) or salt spray tests.

AISI 316 Stainless Steel Pipe Non-Destructive Testing (NDT):

Eddy current, hydrostatic testing, or ultrasonic inspection for defects.

These or other test shall be in accordance with Specification A 999/A 999M.

Schedule and weight chart of AISI 316 Stainless steel Pipe

AISI 316 Stainless Steel Pipe Delivery Standard:

a. Packaging Requirements:

Protective end Caps

Wooden Crates/Wrapping(e.g., plastic film)

Labeling: Clearly mark pipe grade (316/UNS S31600), size, heat number, and standards (e.g., ASTM A312).

b. Documentation:

Material Test Certificates (MTC): Include chemical composition, mechanical properties, and test results.

Certifications

Customs Declarations

Through above, HT PIPE Producing 316 stainless steel pipes requires strict control over material selection, welding/heat treatment, and surface finishing. During delivery, the necessary tests, proper packaging, documentation, and handling are essential to maintain quality. As a partner and supplier, HT PIPE ensures all the products with international standards and reliable performance in critical applications.

Besides the stainless steel pipe, our another core business is the prefabricated welding service, HT PIPE can weld 316 steel pipes to flanges or fittings according to customer drawings or requirements, which greatly reduces the time and cost of installation at the customer's site.