| ASME SA213 /ASTM A213 |

Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes |

| Material Grade |

T2 |

K11547 |

T5 |

K41545 |

T5b |

| T17 |

K12047 |

T21 |

K31545 |

T21 |

| T92 |

K92460 |

T122 |

K91271 |

T911 |

| TP304H |

S30409 |

TP304LN |

S30453 |

TP304L |

| TP310Cb |

S31040 |

TP310H |

S31009 |

TP310HCb |

| TP316H |

S31609 |

TP316L |

S31603 |

TP316N |

| TP321H |

S32109 |

TP347 |

S34700 |

TP347H |

| S30615 |

S30815 |

S31050 |

S21500 |

S31725 |

| K51545 |

T5c |

K41245 |

T9 |

K90941 |

| K21590 |

T23 |

K40712 |

T24 |

K30736 |

| K91061 |

TP201 |

S20100 |

TP202 |

S20200 |

| S30403 |

TP309Cb |

S30940 |

TP309H |

S30909 |

| S31041 |

TP310HCbN |

S31042 |

TP310S |

S31008 |

| S31651 |

TP316LN |

S31653 |

TP317 |

S31700 |

| S34709 |

TP347LN |

S34751 |

TP348 |

S34800 |

| S31726 |

S32615 |

S33228 |

TPXM-19 |

S20910 |

| K11597 |

T12 |

K11562 |

K21001 |

T91 |

| TP304 |

S30400 |

TP304N |

S30451 |

T11 |

| TP309HCb |

S30941 |

TP309S |

S30908 |

T36 |

| S31272 |

TP316 |

S31600 |

TP347HFG |

K90901 |

| TP317L |

S31703 |

TP321 |

S32100 |

TP348H |

| S34809 |

XM-15 |

S38100 |

S25700 |

|

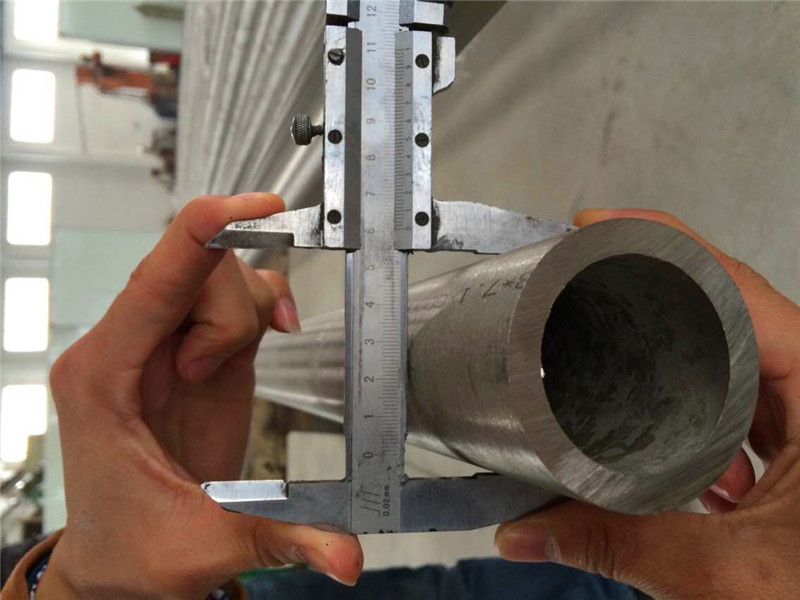

| Size |

1/2''~48'' |

| Thickness |

SCH5~SCHXXS |

| End |

Beveled End,Plain End |

| Length |

As per your requirement. |

| Packing |

Export Standard packing or as per your requirements. |

ASTM A213 TP316H seamless steel tubes are a type of high-temperature and corrosion-resistant steel tubing. They are widely used in industries that require high levels of heat resistance, such as the petrochemical, chemical, and power generation industries.

The TP316H seamless steel tubes are made using a high-quality stainless steel alloy that contains high levels of chromium, nickel, and molybdenum. These elements provide the tubes with impressive corrosion resistance properties, making them excellent for use in highly corrosive environments.

TP316H stainless steel pipe Chemical Composition

| Grade |

UNS |

C≤ |

Mn |

P≤ |

S≤ |

Si≤ |

Cr |

Mo |

Ni |

| TP316H |

S31609 |

0.04-0.10 |

2 |

0.045 |

0.03 |

1 |

16.0-18.0 |

2.00-3.00 |

11.0-14.0 |

ASTM A213 TP316H seamless tubes Mechanical Properties

| Grade |

UNS |

Tensile Strength, Min. Ksi [MPa] |

Yield Strength, min. Ksi [MPa] |

Elongation in 2 in. or |

Hardness, Max |

| Designation |

50 mm, min, % A, B |

Brinell / Vickers |

Rockwell |

| TP316H |

S31609 |

75 [515] |

30 [205] |

35 |

192HBW/200Hv |

90HB |

The manufacturing process for the TP316H seamless steel tubes involves using a hot working method to form the tubes into the desired shape and size. After the hot working process, the tubes undergo a cold finishing process that involves drawing them through a precision die to achieve a smooth and uniform surface finish.

One of the key benefits of using ASTM A213 TP316H seamless steel tubes is their ability to withstand high pressures and temperatures. They have an operating temperature range of up to 1200°F, making them ideal for use in steam generators, superheaters, and high-pressure piping systems.

Another advantage of TP316H seamless steel tubes is their excellent weldability, allowing them to be easily joined together using standard welding techniques. This feature makes them a popular choice in construction and welding applications.