ASTM A312

Stainless steel Pipe include Seamless and Welded Austenitic Stainless Steel Pipes. ASTM A312 Standard specification covers seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipe intended for high-temperature and general corrosive service.

ASTM A312 Stainless steel Pipe Specification

|

Outer Diameter :

|

1/8" NPS to 30" NPS

|

|

Thickness :

|

0.6 mm to 12.7 mm

|

|

Schedules :

|

SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS.

|

|

Length :

|

Single Random, Double Random & Cut Length

|

|

End :

|

Plain End, Beveled End

|

|

Pipe Type

|

Seamless / ERW/ EFW / Welded / Fabricated Pipe

|

ASTM A312 Stainless steel Pipe Grades: TP304,TP304L, TP304H, TP316,TP316L,316Ti, TP316H, TP317, TP317L, TP321, TP321H, TP310S, Tp347, S31254, 254SMO, N08904, 904L, N08367, N08926 etc.

ASTM A312 Stainless steel Pipe Manufacture:

The ASTM A312 Pipe shall be manufactured either hot finished or cold finished.

The Seamless (SMLS) Pipe shall be made by a process that does not involve welding at any stage of production.

The Welded Pipe shall be made using an automatic welding process with no addition of filler metal during the welding process.

The Heavily cold-worked (HCW) Pipe shall be made by applying cold working of not less than 35 % reduction in thickness of both wall and weld to a welded pipe prior to the final anneal. No filler shall be used in making the weld. Prior to cold working, the weld shall be 100 % radiographically inspected in accordance with the requirements of ASME Boiler and Pressure Vessel Code.

The more details about the Material grades Chemical Requirements, Annealing Requirements, Tensile Requirements etc. please check the Standard ASTM A312 pdf.

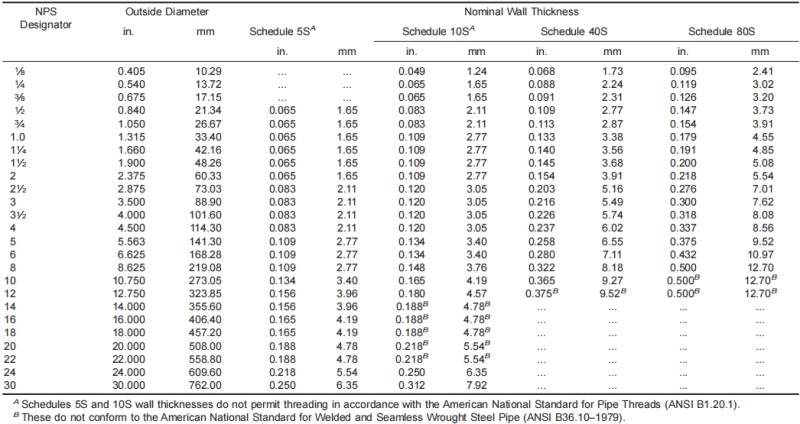

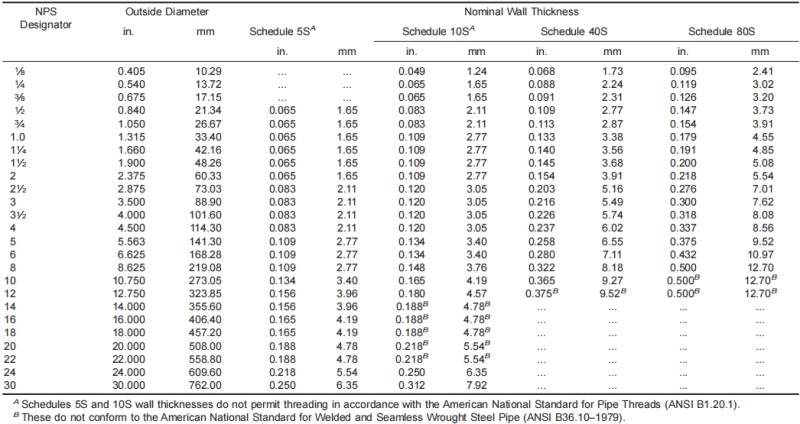

The Dimensions of ASTM A312 Welded and Seamless Stainless Steel Pipe

ASTM A312 Stainless Steel Pipes OD Tolerance

|

Standard

|

OD(mm)

|

|

OD(mm)

|

Tolerance

|

|

ASTM A312

|

10.29~48.26

|

+0.4/-0.8

|

|

48.26~114.30

|

+0.8/-0.8

|

|

114.30~219.08

|

+1.6/-0.8

|

|

219.08~457.20

|

+2.4/-0.8

|