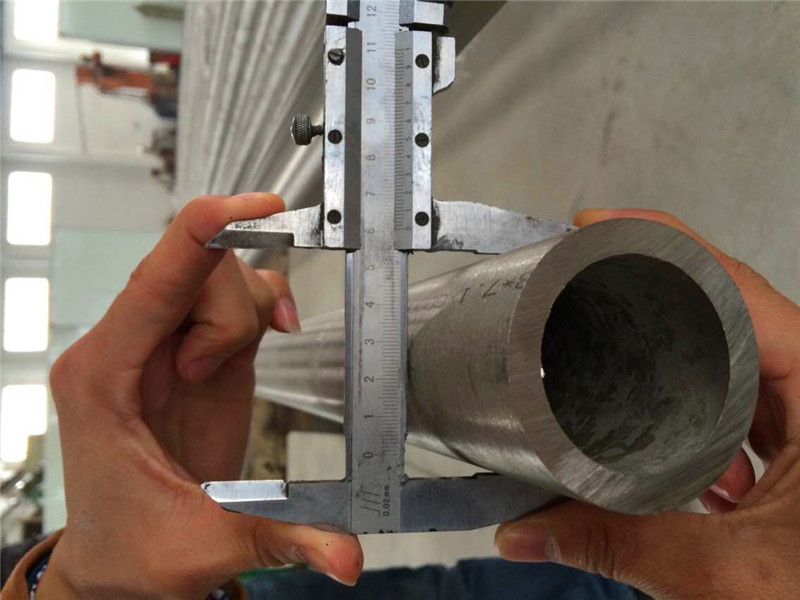

HT PIPE provide Incoloy 800 Seamless and Welded Pipes for the Oil and Gas, Petrochemical and Power Industries. Incoloy pipes supplier in China. ASTM B407 Incoloy 800 Seamless pipe, Incoloy 800 Seamless tube, 1.4876 Incoloy Seamless pipe, 1.4876 Seamless tube, Incoloy seamless pipe and tube supplier, exporter.

Incoloy 800(Alloy 800, UNS N08800, 1.4876) is an iron-nickel-chromium alloy with moderate strength and good resistance to oxidation and carburization at elevated temperatures. Alloy 800 has excellent resistance to stress corrosion cracking in chloride, low concentration NaOH aqueous solution and high temperature and high pressure water, so it is used to manufacture stress corrosion cracking resistance equipment.

The temperature range of Incoloy 800 is 1200℃~950℃, and the cooling method is water quenching or rapid air cooling. For optimum properties and creep resistance, solution treatment should be performed after hot working. The material can be directly fed into a furnace that has been heated to 1200°C, and is quickly released from the furnace after a sufficient heat preservation time, and thermal processing is performed within the specified temperature range. When the material temperature drops below the thermal processing temperature, reheating is required.

Cold working

1. The work hardening rate is greater than that of austenitic stainless steel, so it is necessary to select the processing equipment. Cold-worked materials should be in solution heat-treated state, and intermediate annealing should be performed when the amount of cold work is large.

2. If the amount of cold working is greater than 10%, the workpiece needs to be subjected to secondary solution treatment.

The Chemical Composition of Incoloy 800, %

| Ni |

Cr |

Fe |

Ti |

Al |

C |

Mn |

Si |

S |

Cu |

| 30.0-35.0 |

19.0-23.0 |

≥39.5 |

0.15-0.60 |

0.15-0.60 |

≤0.10 |

≤1.50 |

≤1.00 |

≤0.015 |

≤0.75 |

Physical Properties of Incoloy 800

| Density |

Melting Range |

Specific Heat |

Electrical Resistivity |

| g/cm3 |

°C |

°F |

J/kg. k |

Btu/lb.°F |

µΩ·m |

| 7.94 |

1357-1385 |

2475-2525 |

460 |

0.11 |

989 |

Mechanical Properties of Incoloy 800 Pipe

| Tensile Strength, min. |

Yield Strength, min. |

Elongation,min. |

Hardness, min. |

| Mpa |

ksi |

Mpa |

ksi |

% |

HB |

| 600 |

87 |

295 |

43 |

44 |

138 |

Incoloy 800 Pipe Equivalent Grades

| STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

OR |

| Incoloy 800 |

1.4876 |

N08800 |

NCF 800 |

NA 15 |

ЭИ670 |

Z8NC32-21 |

X10NiCrAlTi32-20 |

XH32T |