| ASTM B423 /ASME SB423 |

Standard Specification for Nickel-Iron-Chromium-Molybdenum-Copper Alloy

(UNS N08825, N08221, and N06845) Seamless Pipe and Tube |

| Material Grade |

UNS N08825 |

UNS N08221 |

UNS N06845 |

|

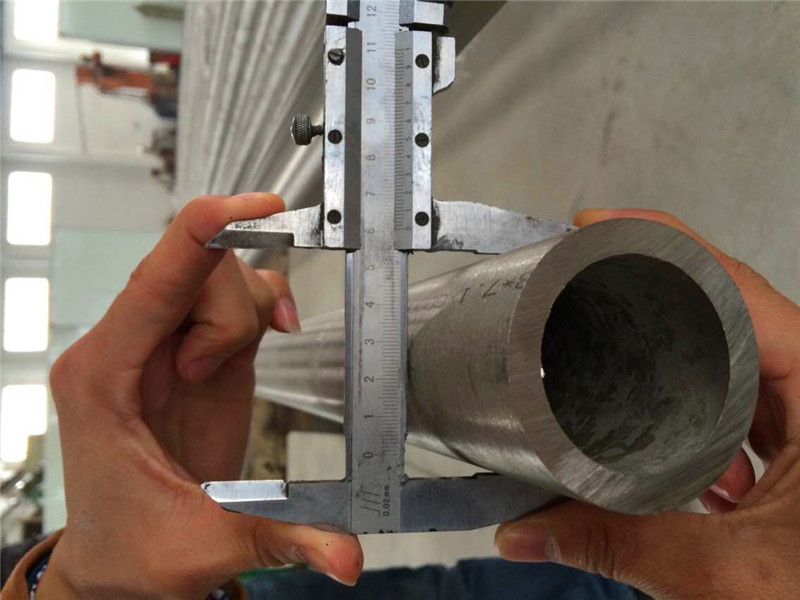

| Size |

1/2''~48'' |

| Thickness |

SCH5~SCHXXS |

| End |

Beveled End,Plain End |

| Length |

As per your requirement. |

| Packing |

Export Standard packing or as per your requirements. |

HT PIPE supplys ASTM B423 UNS N08825 Seamless pipe, Alloy 825 Seamless pipe, UNS N08825 seamless tube, 2.4858 seamless pipe and tube supplier, Incoloy 825 pipe and tube exporter.

Incoloy 825 (UNS N08825, 2.4858)is a nickel-iron-chromium alloy with additions of molybdenum, copper and titanium. It is an alloy that provides high levels of corrosion resistance to both moderately oxidizing and moderately reducing environments. Alloy 825 is similar to alloy 800 but has improved resistance to aqueous corrosion. The high nickel content makes the alloy effective against stress corrosion cracking. It has good corrosion resistance in various media, such as sulfuric acid, phosphoric acid, nitric acid and organic acids, and alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solutions. The higher comprehensive performance of Incoloy 825 is manifested in nuclear combustion dissolvers with various corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide what allows this alloy to have a broad usefulness and wide range of applications.

Fabrication of Incoloy 825

Incoloy 825 can be readily hot or cold worked. Hot working should be in the range 870 – 1180°C, finishing at 870 – 980°C. For maximum corrosion resistance hot worked parts should be stabilise annealed before use. The alloy is easier to cold form than stainless steels.

Incoloy 825 Pipe Chemical Composition, %

| Grade |

C≤ |

Mn≤ |

Si≤ |

S≤ |

Cu≤ |

Fe(min) |

Ni |

Cr |

Al |

Ti |

| Incoloy 825 |

0.05 |

1 |

0.5 |

0.03 |

1.5-3.0 |

22 |

38.0~46.0 |

19.5~23.5 |

0.2 |

0.6-1.2 |

Incoloy 825 Mechanical Properties

| Grade |

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

| Incoloy 825 |

8.14 g/cm3 |

1400 °C (2550 °F) |

Psi – 80,000 , MPa – 550 |

Psi – 32,000 , MPa – 220 |

30% |

Incoloy 825 Equivalent Grades

| STANDARD |

WERKSTOFFNR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

OR |

| Incoloy 825 |

2.4858 |

N08825 |

NCF 825 |

NA 16 |

ЭП703 |

NFE30C20DUM |

NiCr21Mo |

XH38BT |