UNS S32750(Duplex 2507) is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel. Duplex 2507 is designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment.

UNS S32760 is a super duplex stainless steel with a microstructure of 50% austenite and 50% ferrite. UNS S32760 is designed for service in aggressive chloride-containing environments and has additions of W and Cu compared to UNS S32750. It has very good resistance to localized corrosion and stress corrosion cracking in combination with high mechanical strength.

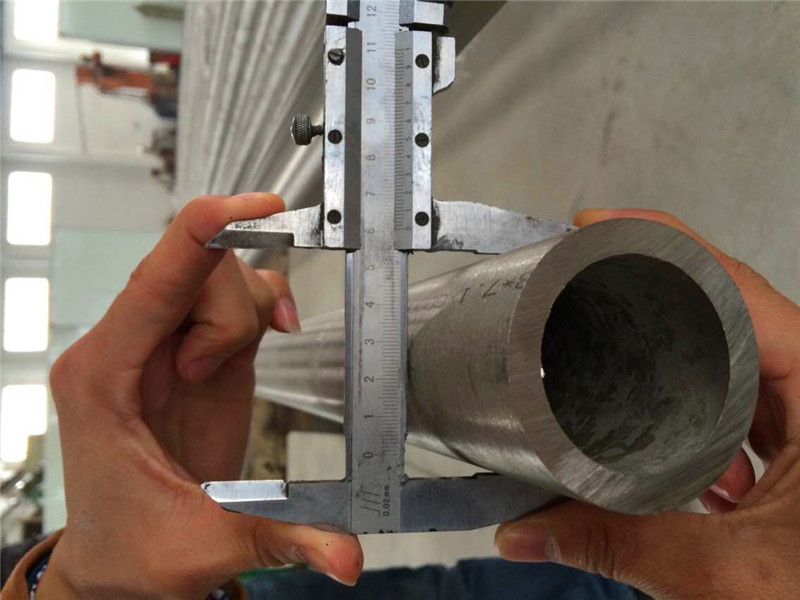

HT PIPE supplys the ASME SA789 Seamless and Welded Tubes and ASME SA790 S31803 Seamless and Welded super Duplex Stainless Steel Pipe for the Oil and Gas, Refinery, Petrochemical and Power Industries.

Super Duplex S32750/S32760 Pipe and Tube stanard:

ASME SA789 /ASTM A789: Standard for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service.

ASME SA790 /ASTM A790: Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe.

S32750/S32760 super duplex Pipe size:

Seamless Pipe size: 4 to 219mm; W. T.: 0.5 to 20mm

Seamless Tube Size: 3.35 mm To 101.6 mm (OD)

Welded Pipe size: 5.0 mm – 1219.2 mm

S32750/S32760 super duplex Pipe Schedule:

SCH5, SCH10, SCH10S, SCH20, SCH30, SCH40, SCH40S, STD, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXSS31803 Pipe Form:Round, Square, Hollow, Rectangular, Hydraulic, Straight Pipes, U bent Tube, Hollow, LSAW Tube Etc.

Seamless Duplex SS Tube Seamless Duplex SS Tube |

A790 S32750 Super Duplex Pipe A790 S32750 Super Duplex Pipe |

Super Dupex S32760 Tube Super Dupex S32760 Tube |

Duplex Welded Pipe Duplex Welded Pipe |

Super Dupex S32760 Pipe Super Dupex S32760 Pipe |

Duplex Welded Tube Duplex Welded Tube |

S32750/S32760 super Duplex Pipe Chemical Composition:

| Grade |

C≤ |

Mn≤ |

P≤ |

S≤ |

Si≤ |

Ni |

Cr |

Mo |

N |

Cu |

| S32750 |

0.03 |

1.20 |

0.035 |

0.02 |

0.80 |

6.0-8.0 |

24.0-26.0 |

3.0-5.0 |

0.24-0.32 |

0.5 |

| S32760 |

0.05 |

1.00 |

0.03 |

0.01 |

1.00 |

6.0-8.0 |

24.0-26.0 |

3.0-4.0 |

0.20-0.30 |

0.50–1.00 |

S32750/S32760 super duplex Pipe Mechanical Properties:

| Mechanical properties |

Tensile, min, ksi[MPa] |

Yield, min, ksi[MPa] |

Elongation, %(min) |

Hardness, HB(max) |

| S32750 |

116 [800] |

80 [550] |

15 |

300 |

| S32760 |

109 [750] |

80 [550] |

25 |

300 |

Equivalent Grades for S32750/S32760 super Duplex Stainless Steel Pipe:

| STANDARD |

UNS |

WERKSTOFF NR. |

| Super Duplex S2507 |

S32750 |

1.4410 |

| Super Duplex S32760 |

S32760 |

1.4501 |

Test:

Hardness Test

Flattening Test

Pitting Resistance Test

Chemical Analysis – Spectro Analysis

Micro and MacroTest

Flaring TestIntergranular Corrosion (IGC) Test

Mechanical Testing Such as Tensile of Area

Positive Material Identification (PMI Testing)

Applicaiton:

Oil Tube, Gas Tube, Fluid Tube, Boiler and Heat exchanger

Seamless Duplex SS Tube

Seamless Duplex SS Tube A790 S32750 Super Duplex Pipe

A790 S32750 Super Duplex Pipe Super Dupex S32760 Tube

Super Dupex S32760 Tube Duplex Welded Pipe

Duplex Welded Pipe Super Dupex S32760 Pipe

Super Dupex S32760 Pipe Duplex Welded Tube

Duplex Welded Tube