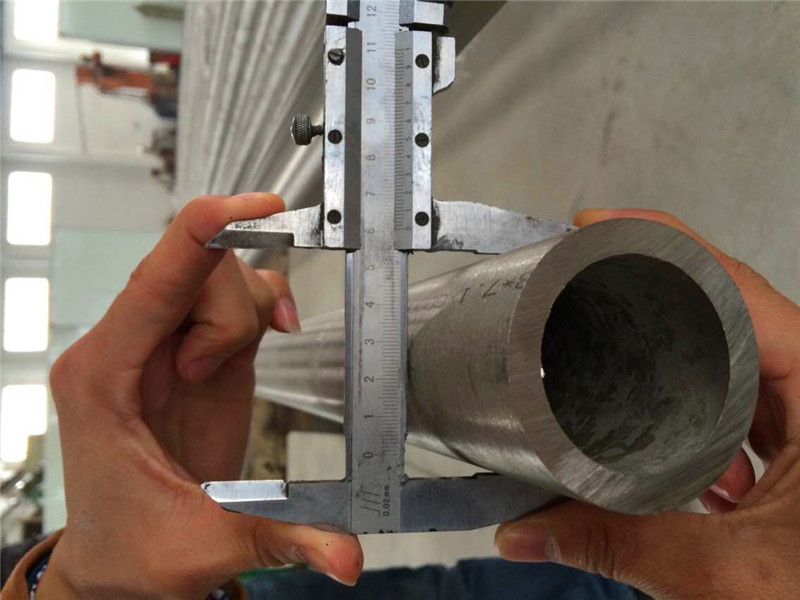

| Size |

1/2''~48'' |

| Thickness |

SCH5~SCHXXS |

| End |

Beveled End,Plain End |

| Length |

As per your requirement. |

| Packing |

Export Standard packing or as per your requirements. |

HT PIPE supplys ASTM B622 Hastelloy X Seamless pipe, Alloy X Seamless pipe, Hastelloy X welded Pipe, UNS N06002 seamless tube, 2.4665 seamless pipe and tube supplier, Hastelloy X pipe and tube exporter.

UNS N06002 Hastelloy X seamless welded nickel alloy pipe, Hastelloy® X (UNS N06002/2.4665) is a nickel-chromium-iron-molybdenum alloy with the addition of cobalt and tungsten, that possesses an exceptional combination of oxidation resistance, formability and high temperature strength. It has also been found to be exceptionally resistant to stress-corrosion cracking. Alloy X exhibits good ductility after prolonged exposure at temperatures of 1200, 1400, 1600 °F for 16,000 hours. It has excellent formability and welding characteristics.

Hastelloy X can be forged and, because of its good ductility, can be cold-worked. It can be welded by both manual and automatic welding methods including shielded metal-arc (coated electrodes), gas tungsten-arc (TIG), and gas metal-arc (MIG). Alloy X can also be resistance-welded.

UNS N06002 Hastelloy X Chemical Composition

| Element |

Mo |

Cr |

Fe |

T |

Co |

C |

Si |

Mn |

B |

P |

S |

Ni |

| Min |

8 |

20.5 |

17 |

0.2 |

0.5 |

0.05 |

-- |

-- |

-- |

-- |

-- |

Re |

| Max |

10 |

23 |

20 |

1 |

2.5 |

0.015 |

1 |

1 |

0.01 |

0.04 |

0.03 |

Hastelloy X Physical properties

Melting point: 1260-1355 ℃

Density: 8.30 g/cm3

Hastelloy X Mechanical Properties

| Mechanical properties |

Tensile, min, ksi[MPa] |

Yield, min, ksi[MPa] |

Elongation, %(min) |

| Hastelloy X |

100[690] |

40[276] |

35 |

Hastelloy X Application

Hastelloy X is widely used in various high temperature environments due to its corrosion resistance in various atmospheres at high temperatures and its excellent high temperature strength.

●Industrial and aviation steam turbines (combustors, rectifiers, structural covers)

Industrial furnace components, support rolls, grids, ribbons and radiant tubes

●Spiral tubes in petrochemical furnaces

●High temperature gas cooling nuclear reactor