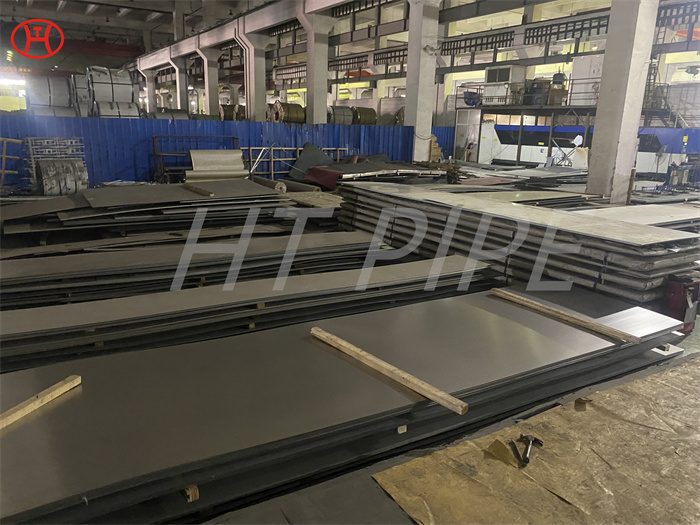

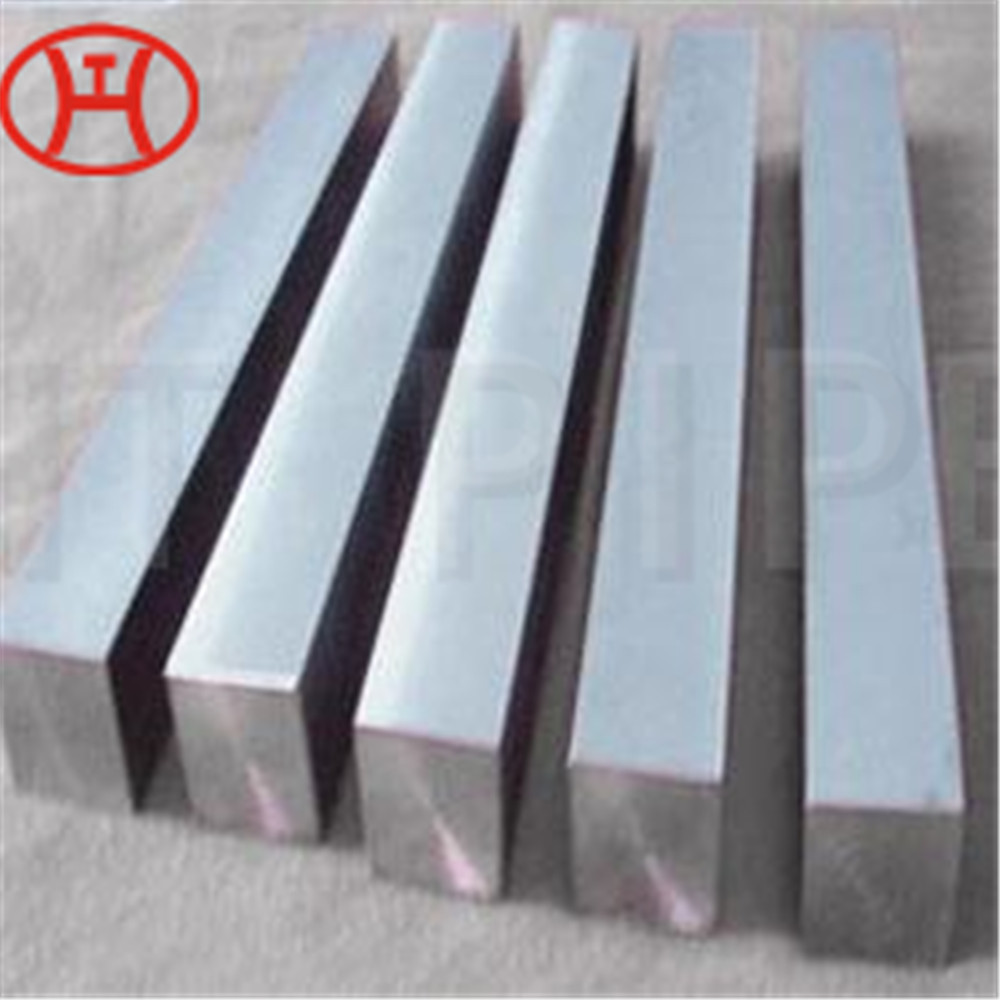

12mm 304ステンレス鋼シート

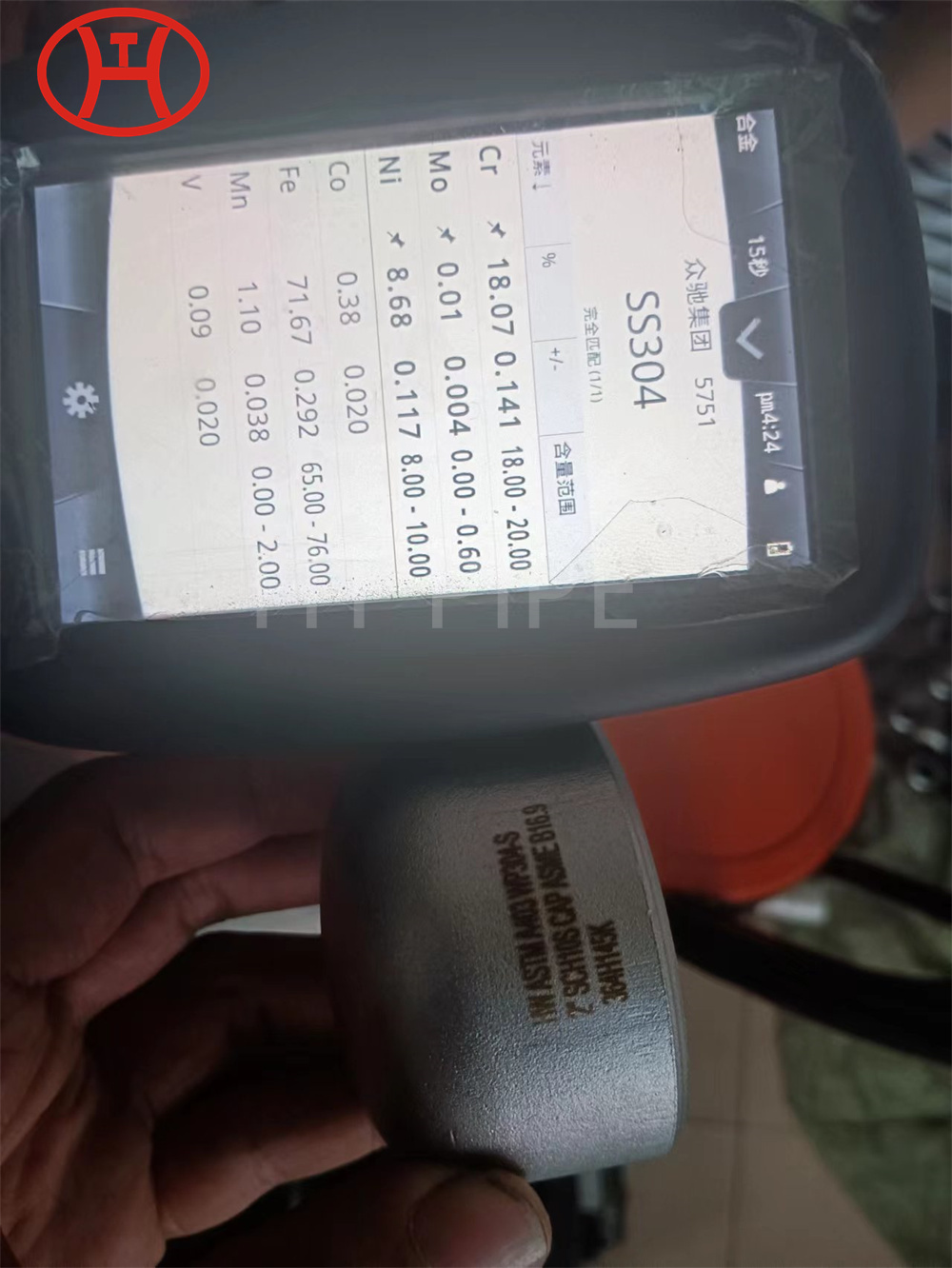

304は優れた機械的特性を持ち、さまざまな腐食剤に耐性があります。 304 \ / 304Lステンレス鋼のコイルとプレートは、オーステナイトステンレス鋼ファミリーの一部です。グレード304は、302および304 \ / 304Lよりも低い炭素含有量を持っています304Lは直接グレード304よりも低い炭素含有量を持っています。304および304Lは、化学、繊維、石油、食品産業の曝露において非常に優れた伸縮性と優れた耐食性があります。

A240 TP304シート、最も人気があり経済的なステンレス鋼です。 A240 TP304シートは、多くの化学腐食剤や産業用大気および海洋環境に対して良好な耐食性を持っています。

A240 TP304シートは、グレード304ステンレス鋼プレートと比較して、主要な機械的性能特性をわずかに減少させます。

304Lの究極の引張強度(UTS)は、約85 ksi(586 MPa)であり、標準グレード304ステンレスのUTよりも少ないです。これは90 KSI(620 MPa)です。降伏強度の差はわずかに大きく、304 SSの降伏強度は42 KSI(289 MPa)と304Lの0.2%の降伏強度35 KSI(241 MPa)です。

A240 TP304シートは、タイプ304およびタイプ316で使用できます。タイプ304は簡単にロール形成または曲がっています。優れた腐食抵抗と溶接性により、最も人気のあるグレードの1つになります。

A240 TP304シートは、衛生と清潔さが重要な場合に役立ちます。 S30403プレートは、アニール状態では非磁性です。コールドワークは硬度と引張強度を高める可能性がありますが、炭素含有量を減らして、その後の熱処理が実行不可能な溶接構造に良好な耐食性を提供することで改善できます。

応用

準備エリアなどのキッチンベンチ、作業面

流し台、冷蔵庫、ビール醸造、牛乳加工、ワイン製造、クリームディスペンサー、あらゆる種類の乳製品などの飲料加工などの飲料加工

化学容器

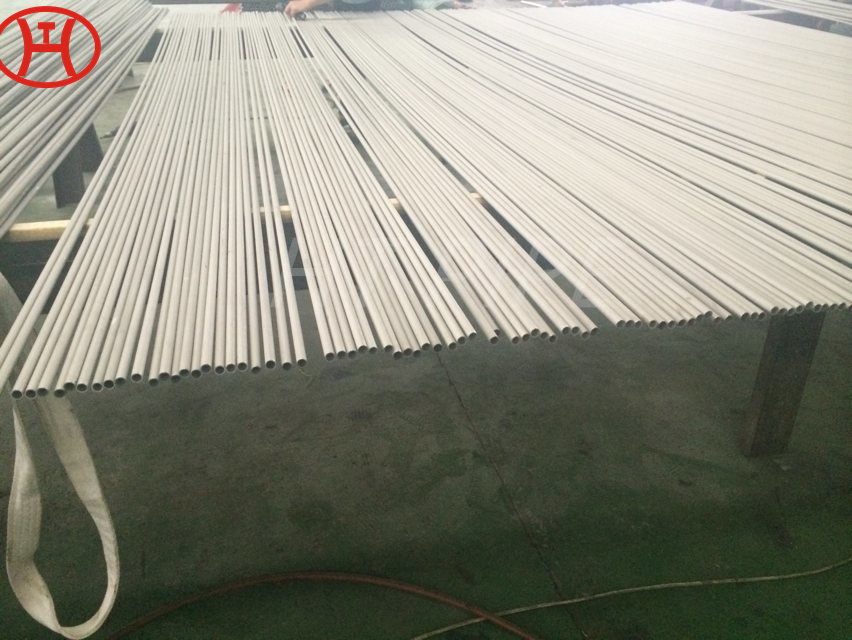

熱交換器

アーキテクチャのトリムとモールディング

石油化学および石油精製

採掘、採石、水のろ過用の織や溶接スクリーン

クリーンルームなどの環境の医療または医薬品処理